Our team of skilled engineers provide a complete service. We have key international relationships which helps ensure that we can provide the best local support and assistance. Our engineers are dedicated to solving customers’ problems and reducing downtime.

Alloy Bearings

-

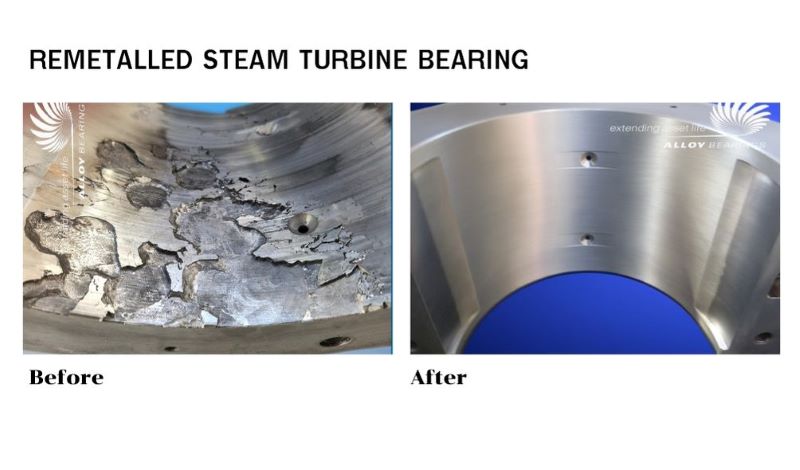

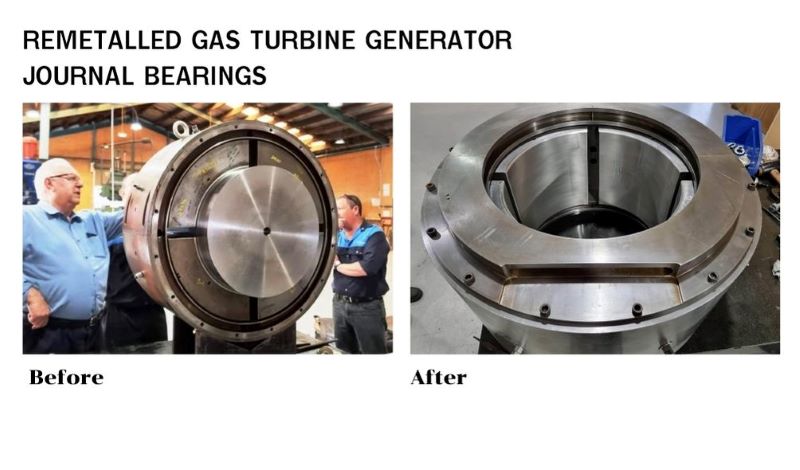

Plain Bearing Remetalling and Machining Services

PRODUCT DETAIL :

Talk about product details via Get a QuoteWe know our customers expect a refurbished bearing to match the performance of that of a new bearing, so we ensure that the same careful control and rigorous techniques are used in the repair work as those of any OEM’s process.

Quality and Service

Alloy Bearings remetals, manufactures and supplies bearings for a wide variety of purposes, meeting exacting demands for performance, quality, price and environmental excellence.

Dedication and Support

Life-cycle management of critical equipment is an essential strategy in today’s changing environment. Minimising risk and preventing downtime are realities that all manufacturing and primary industries should identify as key management issues in order to achieve operational excellence.

-

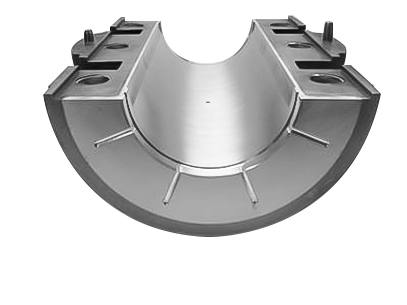

Manufacture of White Metal Bearings

PRODUCT DETAIL :

Talk about product details via Get a QuotePrecision engineering you can rely on

Our team of skilled engineers work together to provide a complete service dedicated to solving our customers’ problems and reducing downtime. A system of regular performance reviews, meticulous documentation and record keeping allow us to provide you with an informed analysis to identify root cause issues and where potential future issues may occur.

Our approach is to implement systems that are not only designed to protect and extend the life of critical equipment but also to eliminate the risk of any costly ‘downtime’ occuring.

We provide:

» CAD drawing capabilities

» Foundry specifically set up for plain bearings

» Reverse engineering and drawing capabilities

» Qualified and experienced machinists

» Extensive database of historical data about plain bearings

» In-house Qualified Operator Level II for Ultrasonic Testing

» Combination of CNC and conventional machining -

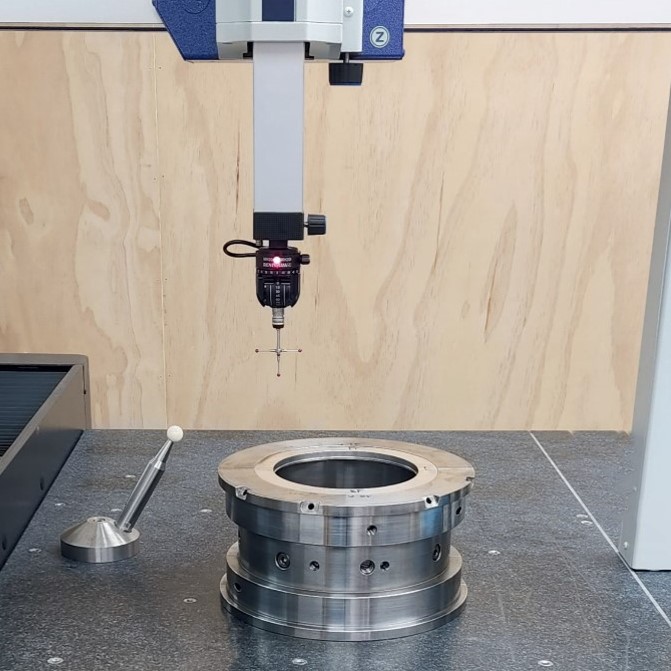

Bearing Health Checks

PRODUCT DETAIL :

Talk about product details via Get a QuoteOften at times a Bearing you have in storage you think is serviceable but it isn’t, whether its due to poor storage, mishandling or even an old bearing in a new box. We have this issue a lot and now we offer a ‘Bearing Health Check’ to inspect and then qualify your spare bearing for use.

This involves precise measurements and visual inspection followed by NDT (Non Destructive Testing) with Dye Penetrant and Ultrasonic Testing to establish whether the Bearing is serviceable or not.

After NDT, we offer our expert advice from our Bearing Specialists with over 200 years combined experience in dealing with Whitemetal Bearings, we can advise whether or not your Bearing is serviceable or needs refurbishment, remetalling or brand new replacement.

GET A QUOTE

THANK YOU

You will be hearing from us soon!

Close