Modular remote I/O systems transmit process data from safe or explosion hazardous areas by connecting binary and analog sensors and actors to the control system via a bus interface. Remote I/O is the right choice when you want to put I/O modules close to the field devices. Due to the reduced wiring effort, you not only save cables, but also time, money, and work effort. Hence, remote I/O field units can be installed in a decentralized location inside hazardous areas while you easily control and monitor sensors and actors from the control room.

You can connect 4 mA … 20 mA devices to remote I/O, including water flow transmitters, valve positioners, pressure transducers, or temperature transmitters. Devices such as thermocouples, resistance temperature detectors (RTDs), mechanical contacts, and visual or audible alarms may also be connected.

Our remote I/O systems are compatible with network protocols like:

- PROFIBUS DP

- PROFINET

- MODBUS RTU

- MODBUS TCP/IP

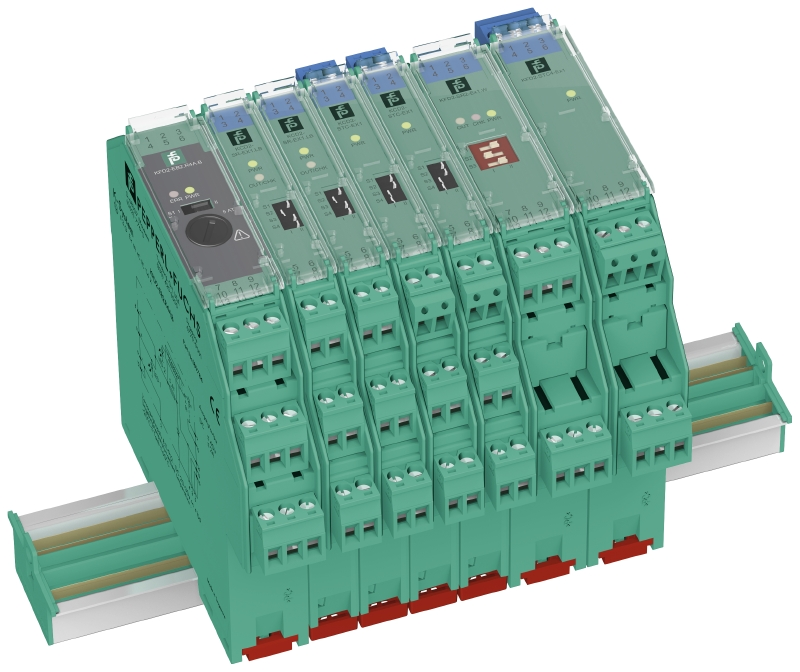

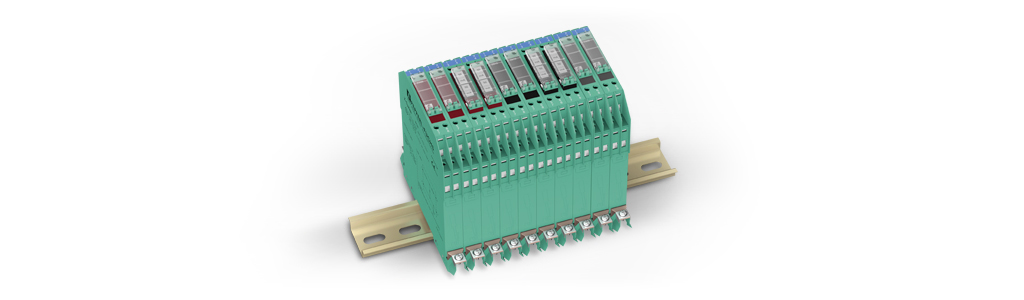

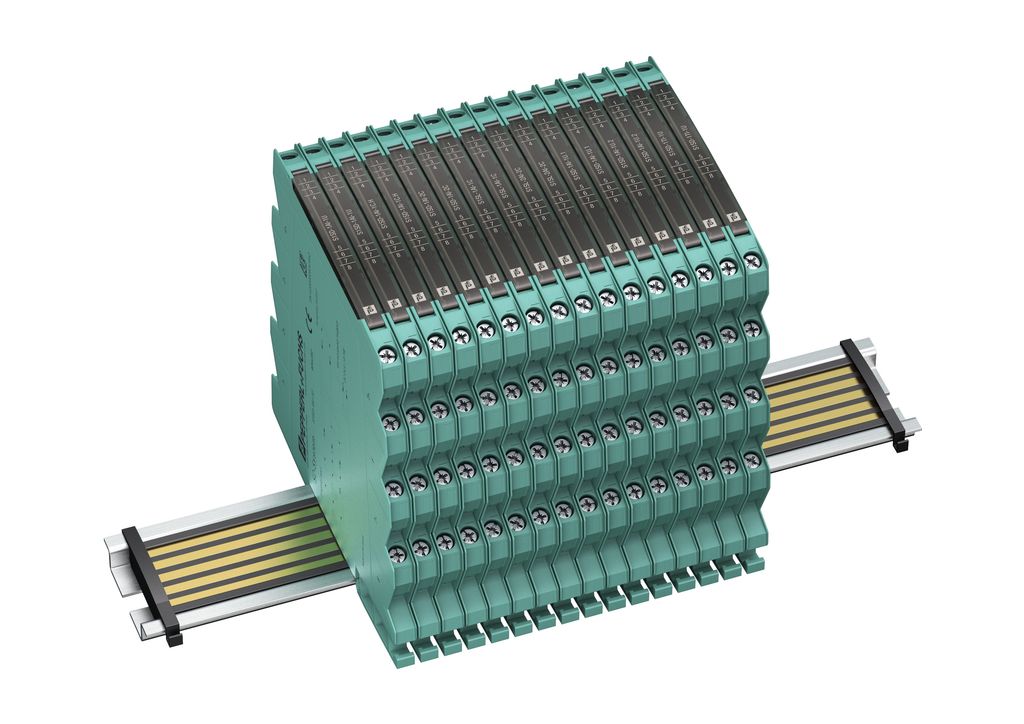

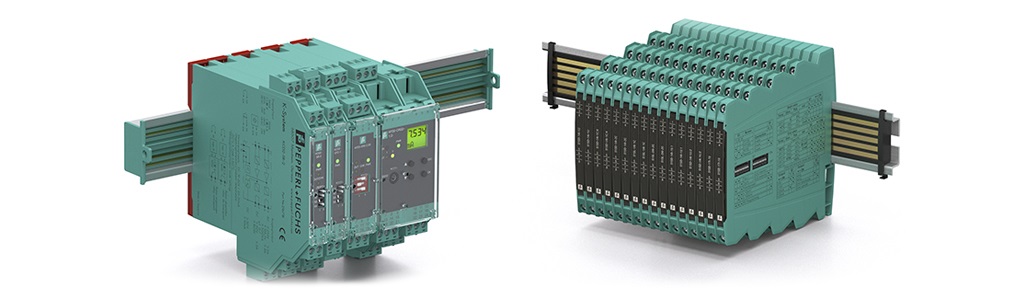

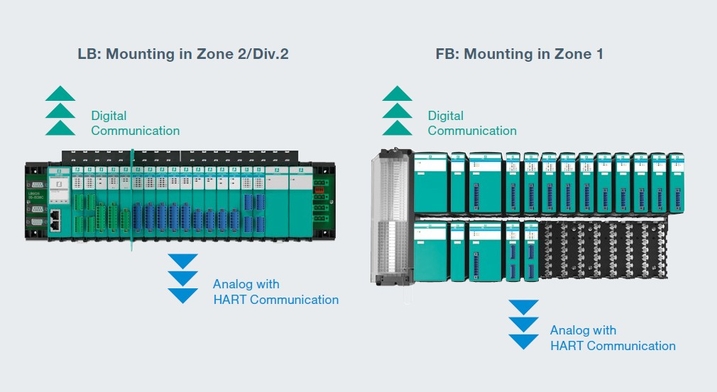

The two systems offered by Pepperl+Fuchs for the use in Zone 1 or Zone 2, the FB remote I/O– and the LB remote I/O system, have another, very important benefit to offer: keeping the topology of both systems the same across the process control level simplifies planning and carrying out maintenance.